Strategic portfolio optimization: WEKA discontinues TLI IndustryLine…

Thermo-acoustic oscillations pose a significant challenge in the operation of cryogenic systems, where extreme temperature differentials in a pipe can lead to detrimental effects on both process efficiency and equipment integrity. At WEKA, we have developed innovative solutions aimed at mitigating these oscillations and ensuring optimal performance of cryogenic installations.

In cryogenic plants, thermo-acoustic oscillations can occur when one end of a pipe is exposed to the very cold process fluid while the other is in contact with ambient temperature. This temperature differential can induce fluid oscillations within the system, resulting in increased heat input and potential freezing of external surfaces—a scenario highly undesirable for cryogenic operations.

Several factors influence the likelihood of thermo-acoustic oscillations:

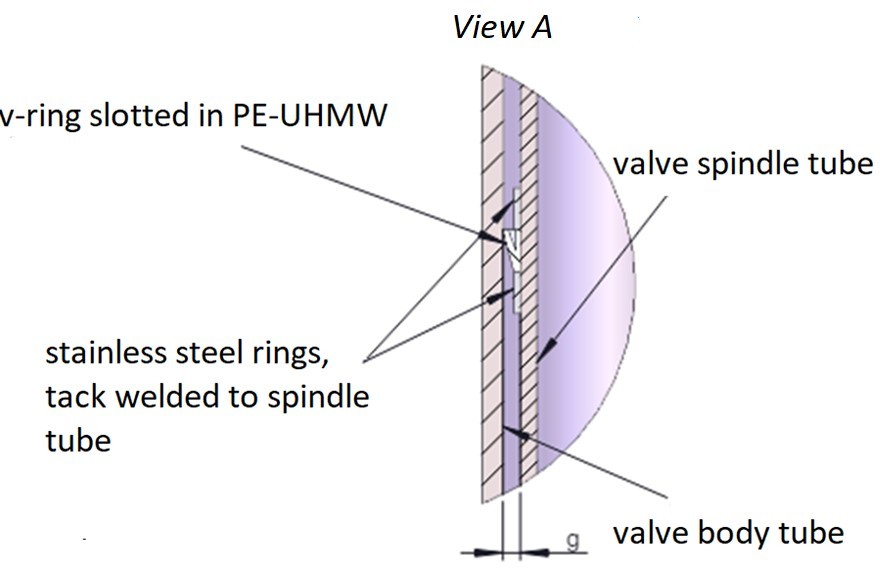

To combat thermo-acoustic oscillations, WEKA has engineered specific solutions tailored for cryogenic valves and plants:

While thermo-acoustic oscillations present a formidable challenge in cryogenic installations, proactive measures can effectively mitigate their occurrence. By implementing solutions such as convection brakes, check valves and thermal intercepts, operators can significantly improve system reliability and performance. At WEKA, we recognize the critical importance of tailored design and meticulous assessment of operational risks to deliver solutions that meet the specific needs of each cryogenic installation.

For more information on how WEKA addresses thermo-acoustic oscillations and other challenges in cryogenic systems, please contact us. Our experts in cryogenic applications are always at your service.