WEKA Solutions for On-/Offshore Applications

Shipbuilding and marine applications place the highest demands on level measurement technology: from standard solutions for conventional ships to highly specialized systems for FPSO units, components must withstand extreme sea conditions and severe corrosion. For decades, WEKA level indicators have proven themselves for a wide range of operating fluids on board - reliable, durable and robust.

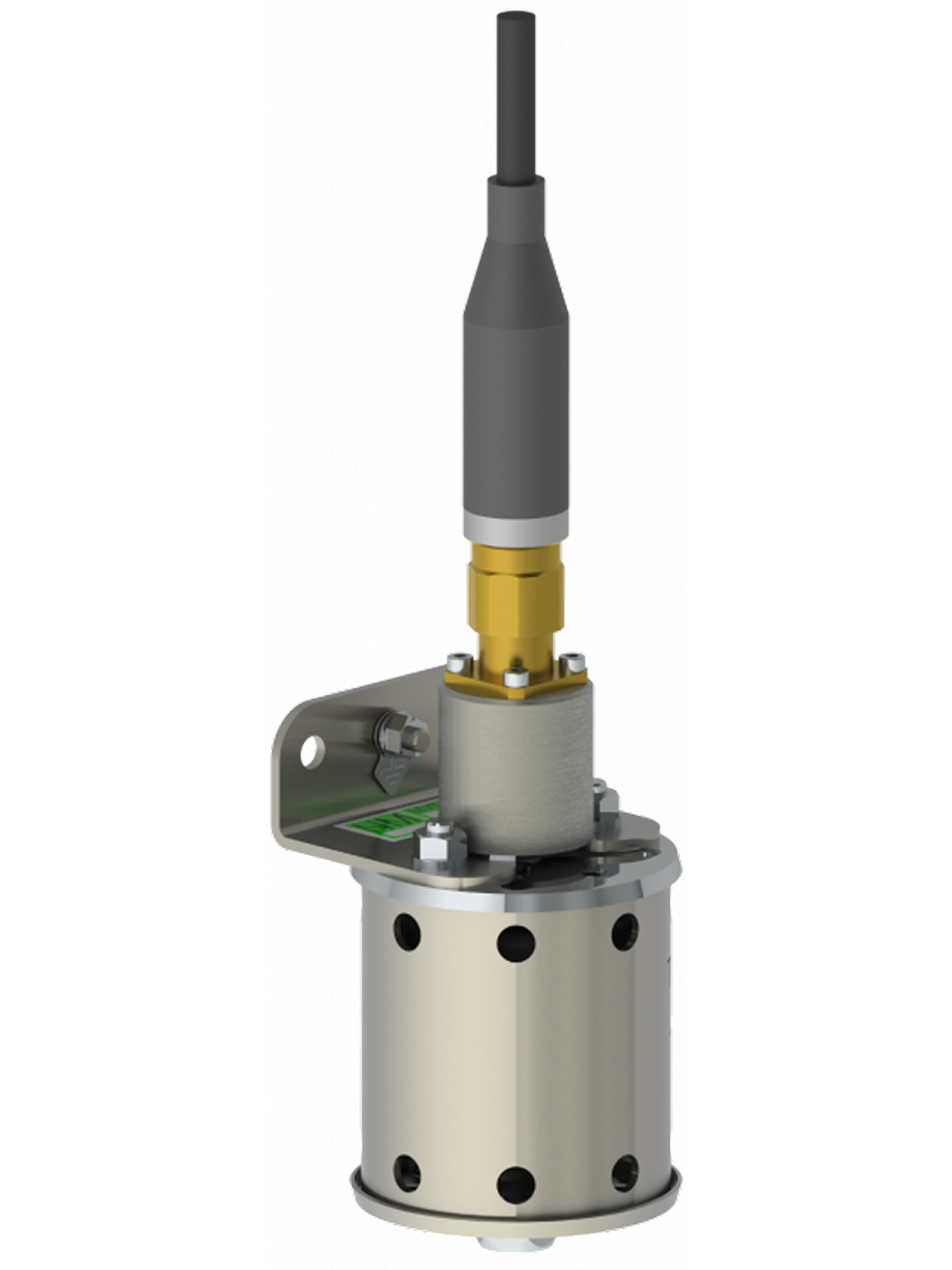

Today, our portfolio goes far beyond classic level technology: with the development and DNV-certified approval of our cryogenic hydrogen valves, we offer solutions for pioneering marine applications in the field of alternative propulsion technologies. This makes WEKA the ideal partner for shipyards and shipping companies that focus on innovation and sustainability. Our product range covers the entire parameter range - from proven standard variants to PED-certified special versions for high-pressure, high-temperature and cryogenic hydrogen applications.

Explore our proven solutions for shipbuilding and maritime applications today.

- Fresh water tanks for drinking water and process water

- Wastewater systems and greywater treatment

- Fuel tanks for marine diesel and heavy fuel oil

- Lubrication systems for engines and gearboxes

- Tank farms for cargo and ballast water

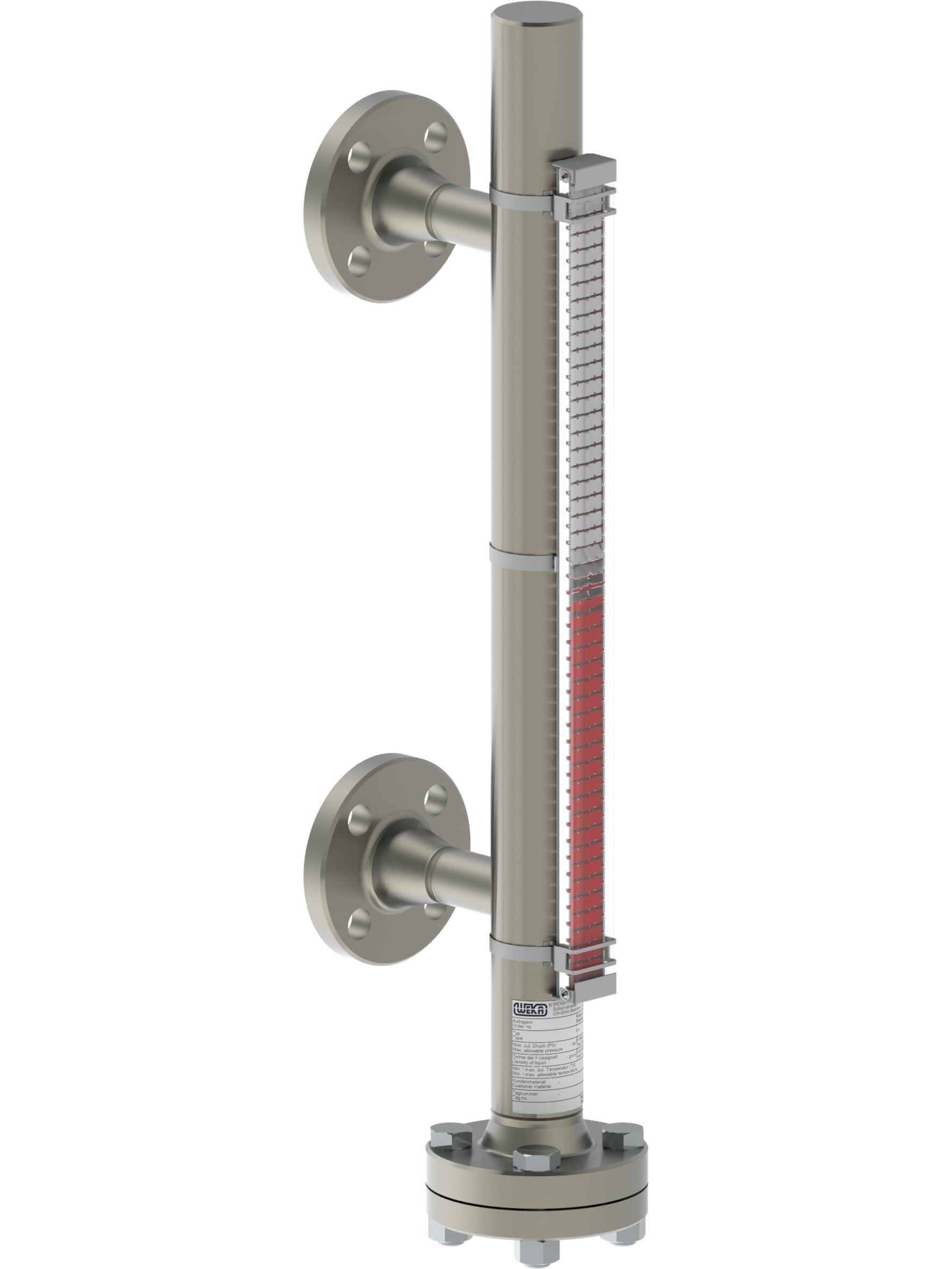

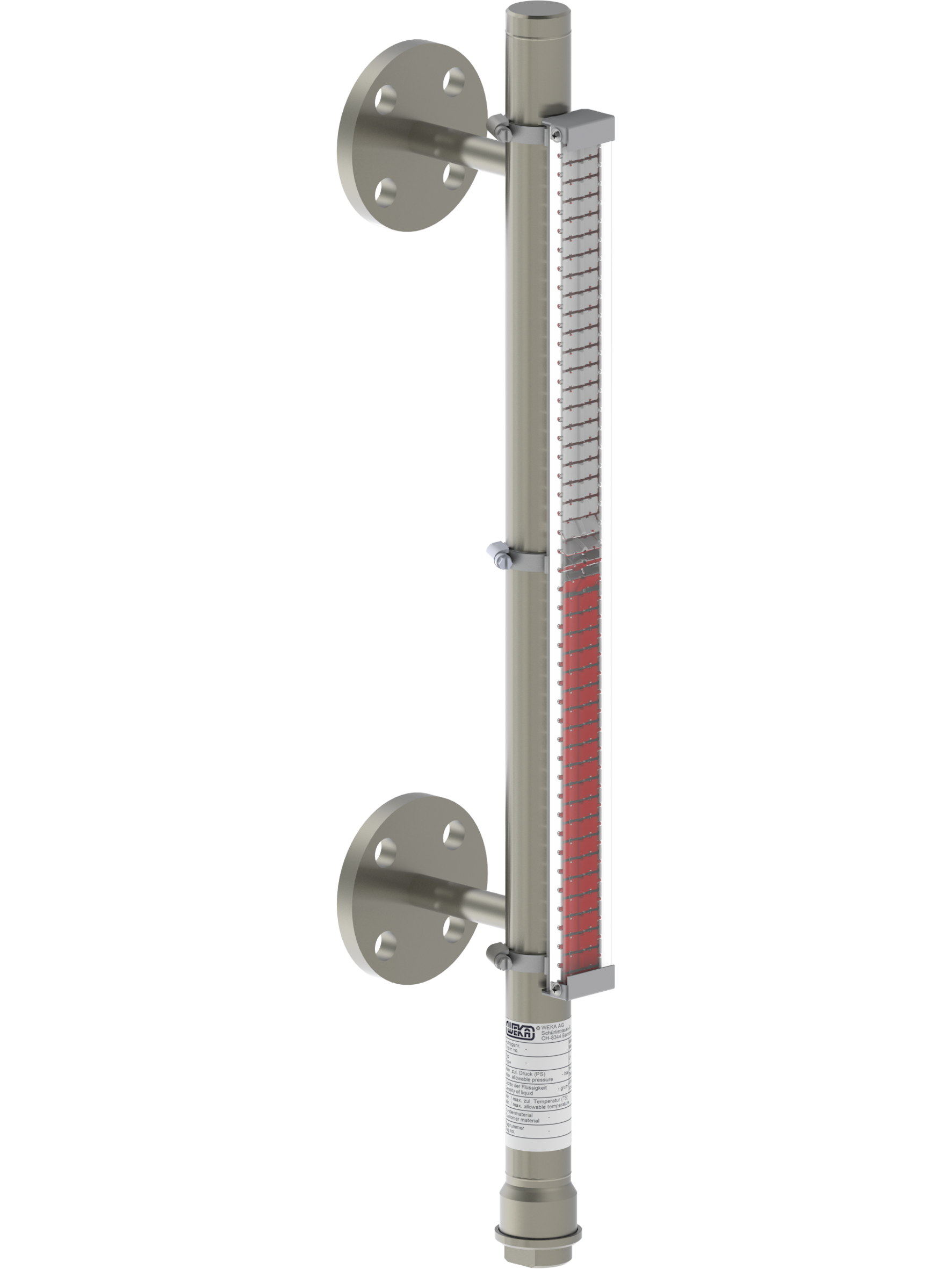

Shipbuilding is one of the most traditional areas of application for WEKA level indicators. Valves and cryogenic components are also increasingly being used in maritime applications, such as in the transport of hydrogen or in cryogenic supply systems. These components must withstand extreme conditions such as salt fog, vibrations, temperature fluctuations, and aggressive media. WEKA products are designed for maximum reliability and safety under these demanding conditions.

Especially for FPSO ships (Floating Production, Storage and Offloading Units) with completely installed, movable drilling towers as well as storage and transshipment stations, specialized level indicators in the high-pressure and high-temperature range are often used. These floating production platforms place extreme demands on materials and construction.

While our standard materials 316/316L are sufficient for most shipbuilding applications, special liquids such as aggressive chemicals, ballast water, or corrosive cargo require specialized materials. Specialized solutions made of high-alloy nickel steels and, in the level measurement range, variants in PVC, PP, and PVDF ensure the necessary resistance to salt water and durability under maritime conditions.

WEKA has most renowned product certifications for shipbuilding and is thus well-equipped for all inquiries from this industrial sector. Our products are designed for maximum safety – certified according to DGRL with conformity assessment according to Module H/H1. This ensures reliable operation even under extreme sea conditions.

For Shipbuilding and maritime applications

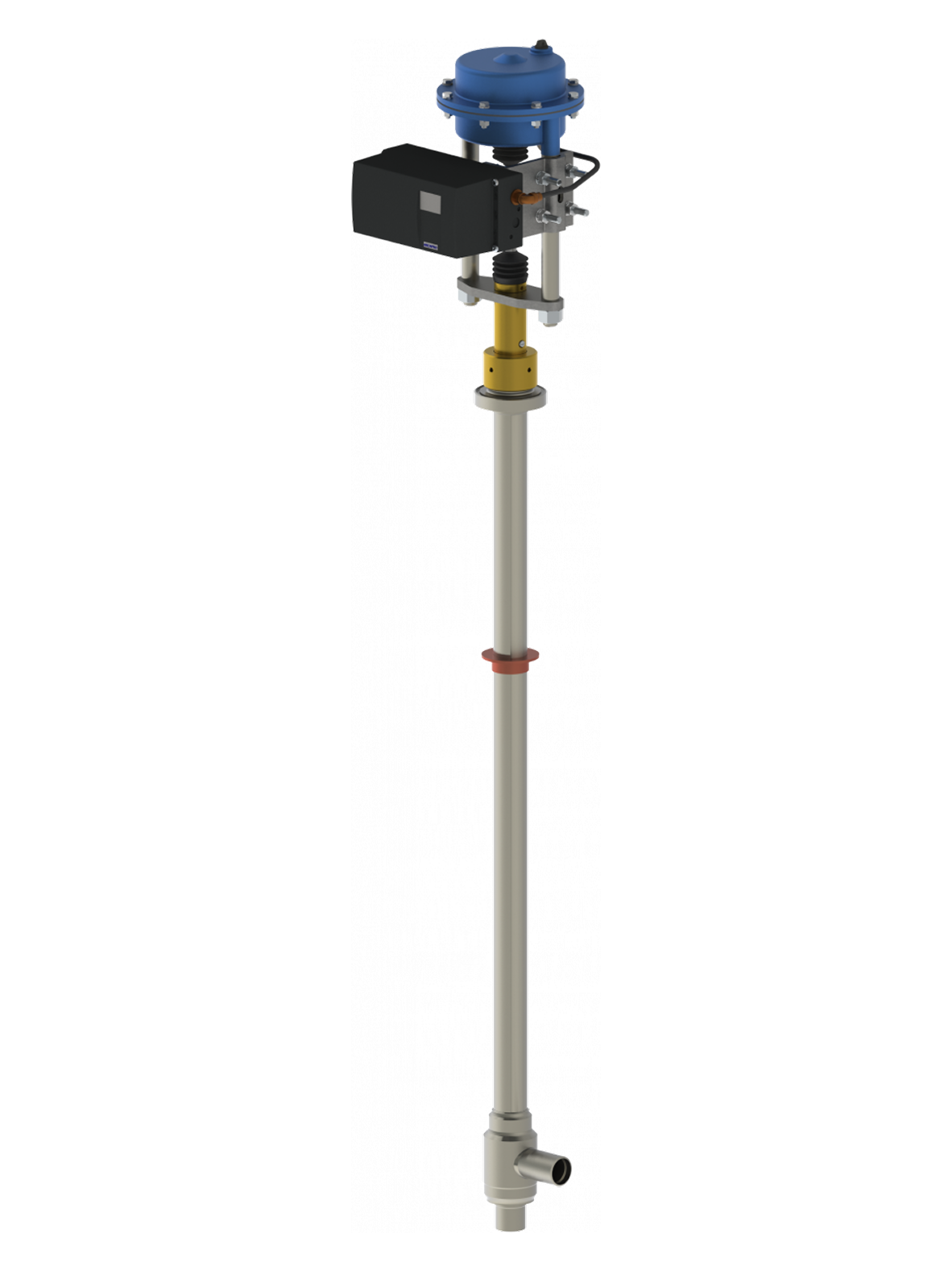

WEKA Products - Valves and Cryogenic Components

For Shipbuilding and maritime applications

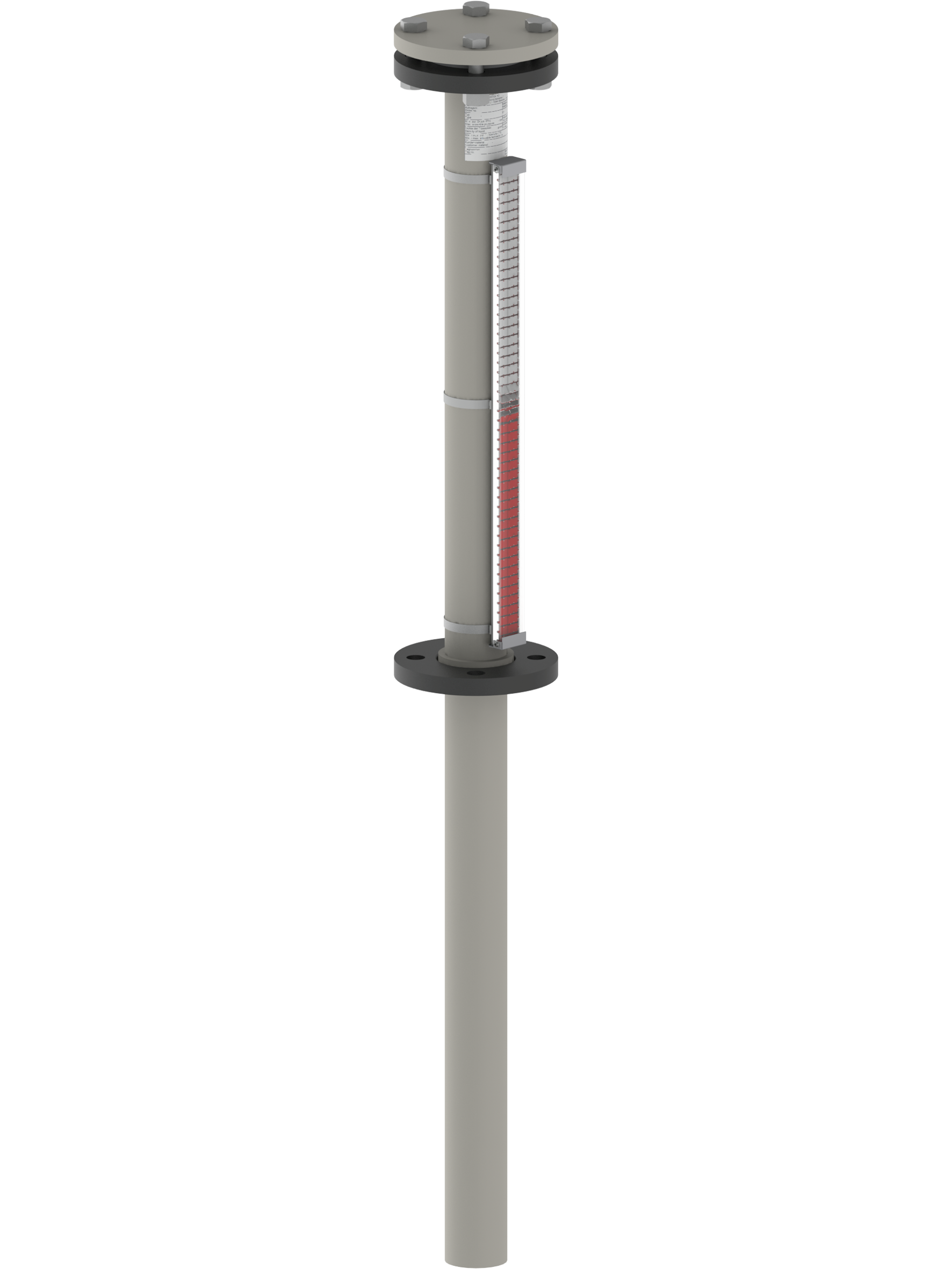

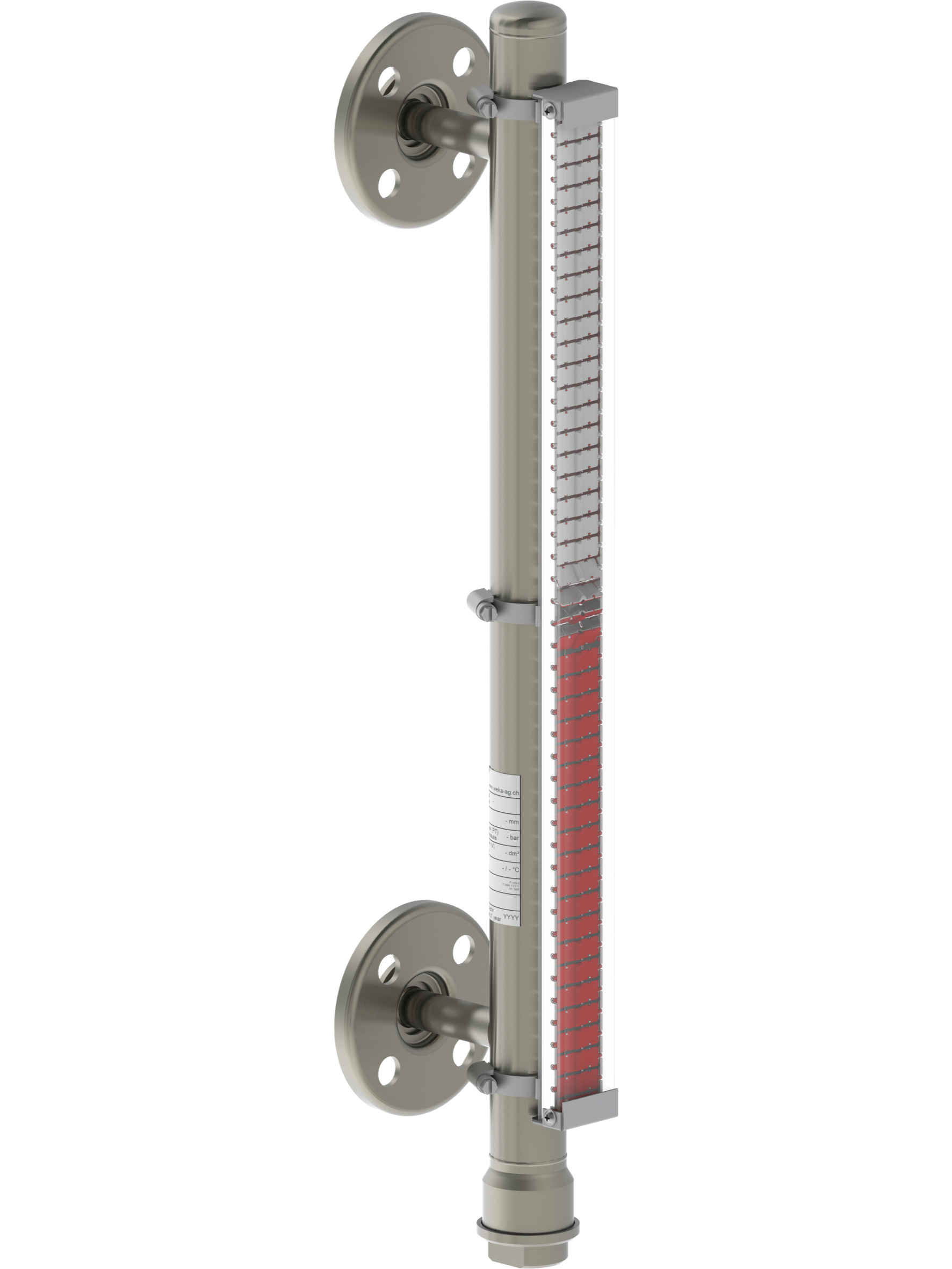

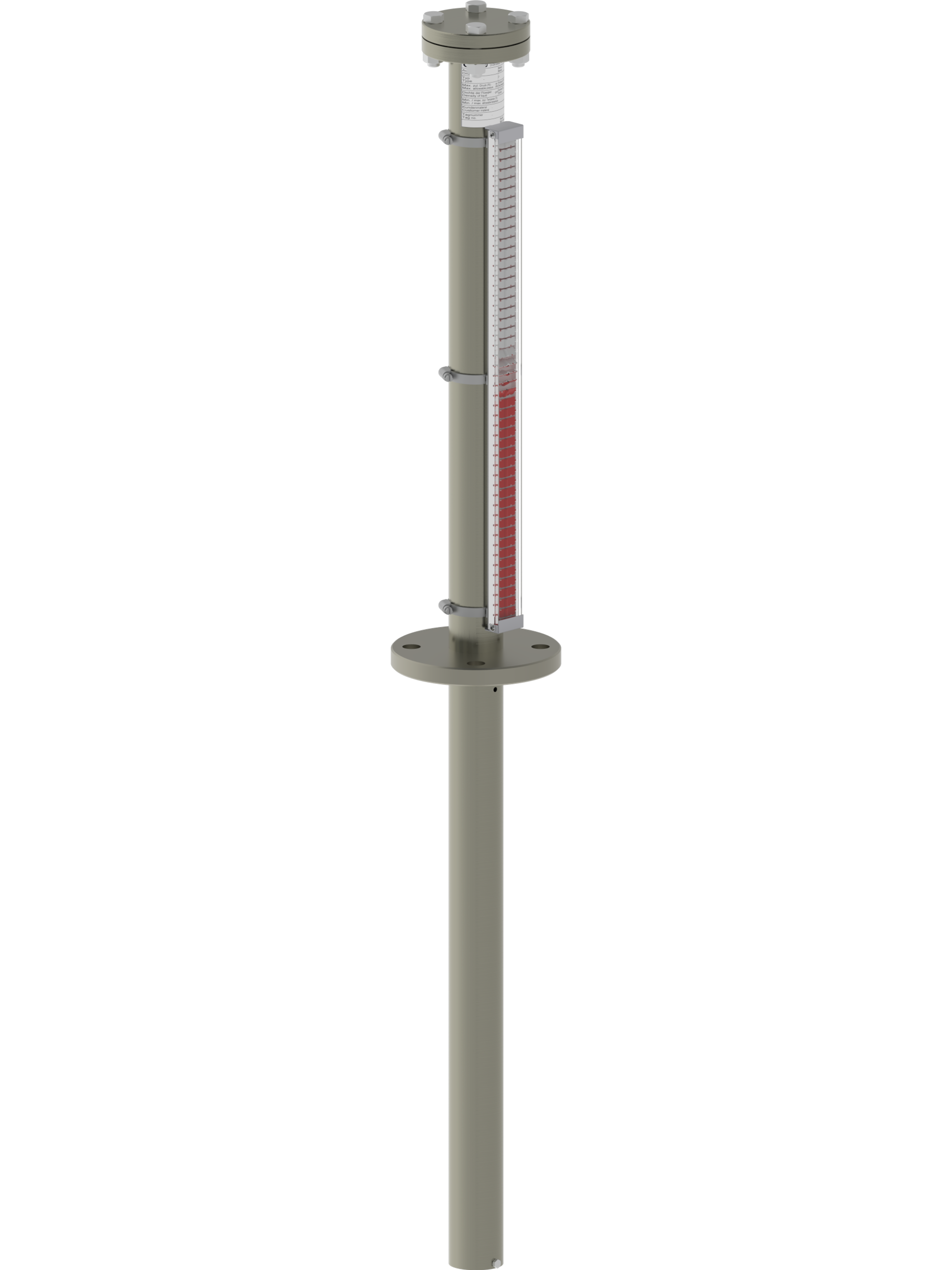

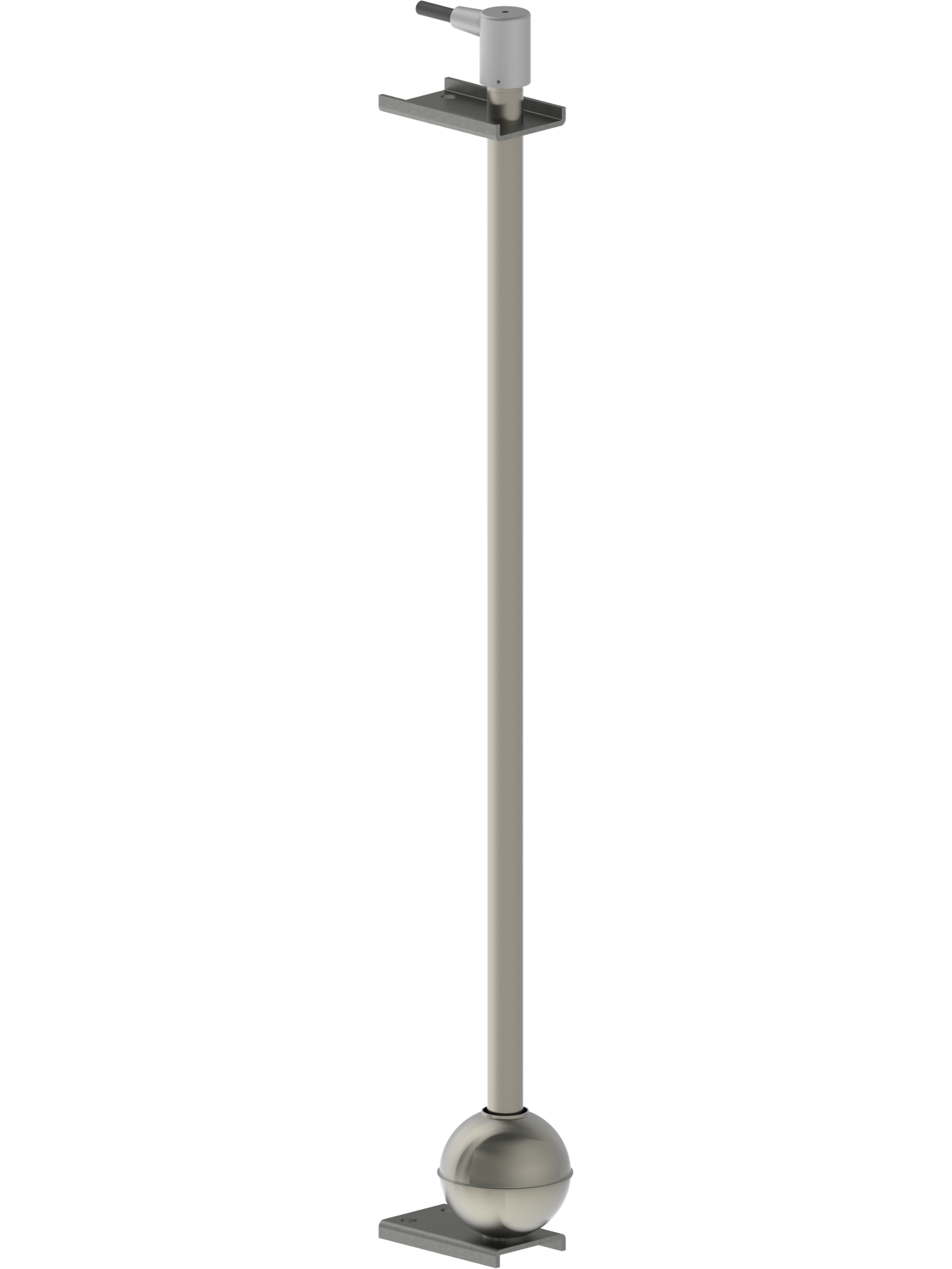

WEKA Products - Level measurement technology

WEKA Competence

For most applications you will find suitable solutions from our WEKA standard range. Special designs for unusual operating conditions in marine projects are possible at any time. Our strengths include development, production and testing of customized solutions for shipbuilding and marine applications.

Get in touch with us – we are happy to advise you on your specific requirements.

Our experts are happy to help

Your personal contact

John M. Andrea

International Sales Manager, Senior Engineer Level Instruments

Send an email+41 43 833 43 27German, English, French

Expert for: East Asia, Russia, India

Leon Trajber

International Sales Manager Valves & Cryogenics

Send an email+41 43 833 43 22German, English, Slovenian, Serbian, Croatian, Hungarian

Expert for: Europe, Americas, Africa

Miralem Okanovic

International Sales Manager Valves & Cryogenics

Send an email+41 43 833 43 20German, English, Croatian