Strategic portfolio optimization: WEKA discontinues TLI IndustryLine…

Bigger is better, this is also true for basic research facilities worldwide. CERN near Geneva, for example, is planning a new, even larger particle accelerator. Another gigantic research facility is being built in South Korea with RAON (Rare isotope Accelerator complex for ON-line experiment) - also with components from WEKA AG, which can satisfy the demand for ever larger control and regulation components.

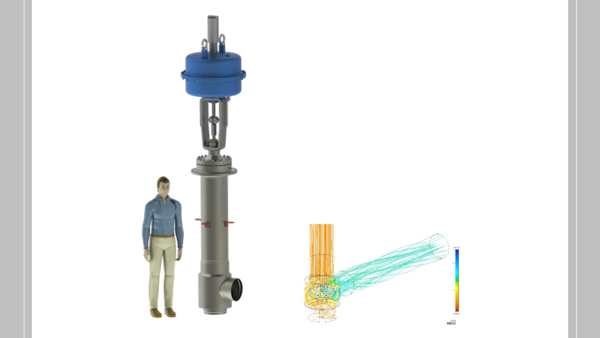

Because the 4 Kelvin cold helium used for cooling now flows through WEKA cryogenic valves with a nominal diameter of DN250 which previously were not available for these temperatures and this flow coefficient. With a length of three meters and a total weight of more than 1.2 tons, the newly developed DN250 control valve also sets new standards. So far WEKA AG has produced valve sizes up to a maximum of DN150. The development and production of what is now the world's largest valve for these conditions required new approaches throughout the entire working process. Thus WEKA AG broke new ground with innovative development methods: CFD simulation was used to quickly and efficiently determine the correct design for the minimum required flow rate. Rapid prototyping was used to produce the housing component, whereby the simulated flow coefficient could be measured and validated. Thanks to many years of experience in the development of valves for use under extreme conditions, these challenges have been mastered. The production of highly demanding parts, but also handling during assembly, the entire welding process and finally transport demanded all the expertise of all WEKA specialists.