Strategic portfolio optimization: WEKA discontinues TLI IndustryLine…

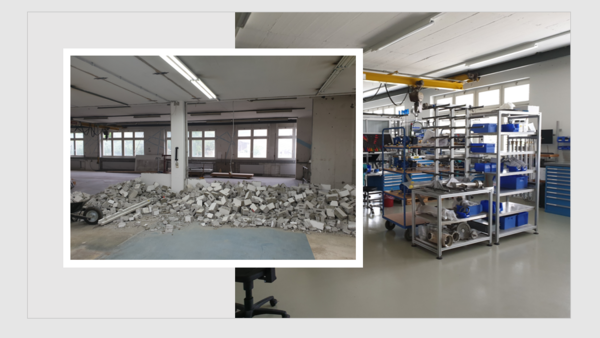

WEKA AG has remodelled its entire production area at the Bäretswil site in Switzerland. The optimised material and production flow as well as other lean measures allow WEKA customers to be offered even shorter delivery times, even for customer-specific piece production.

Global production chains, short delivery deadlines, demand for piece production according to customer-specific requirements - the market dynamics are high in the field of cryogenic components, special valves and level measuring instruments. To accommodate this development, WEKA AG made targeted investments in its production space in June 2020.

The comprehensive remodelling was implemented within the existing building layout and during ongoing production. During the process, WEKA AG implemented various lean measures so that the optimised flow of materials and production enables even higher, more flexible and customer-oriented manufacturing.

WEKA customers now benefit on the one hand from shorter delivery times, and on the other hand from the new focus on the direction of One-piece-flow: Individual piece production in order to be able to produce customer-specific products efficiently and to a high standard of quality. The new workplaces now also offer the best prerequisites for moving into the future in further digitalisation topics. Whether with visually animated and step-by-step assembly instructions or for automatic recording and logging of test results during the production process; there are almost no limits to future automation and digitisation projects.

The remodelling of the production area thus contributes significantly to further growth and to securing the location in Switzerland in the long term. WEKA employees are also pleased about this - and about their workplaces designed according to the latest ergonomic standards.

WEKA AG has a firm grip on liquids and gases - for 80 years and will continue to do so in the future.