Strategic portfolio optimization: WEKA discontinues TLI IndustryLine…

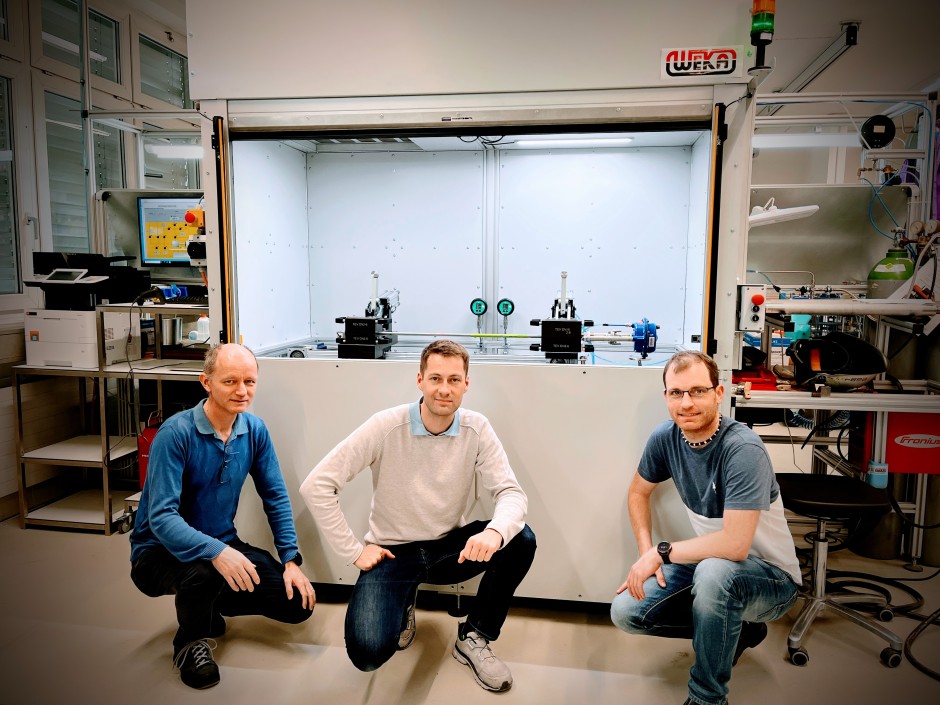

In our efforts to continuously improve efficiency and quality, we have developed a new test bench for valves (DN2 to DN32). This enables automated pressure and leakage testing with gas up to 40 bar and sets new standards in safety and precision.

The development: from prototype to series solution

The first prototype of the test bench was already an important step: it allowed semi-automatic testing, whereby the results were still documented manually. But we wanted more.

In the latest version of the test bench, decisive further developments were implemented:

This project impressively demonstrates what is possible when different departments work closely together. The new test bench is another milestone on our path to combining innovation and quality in a sustainable way.

We look forward to using this solution not only to optimize internal processes, but also to set new standards in the industry.