WEKA Solutions for Cutting-Edge Research

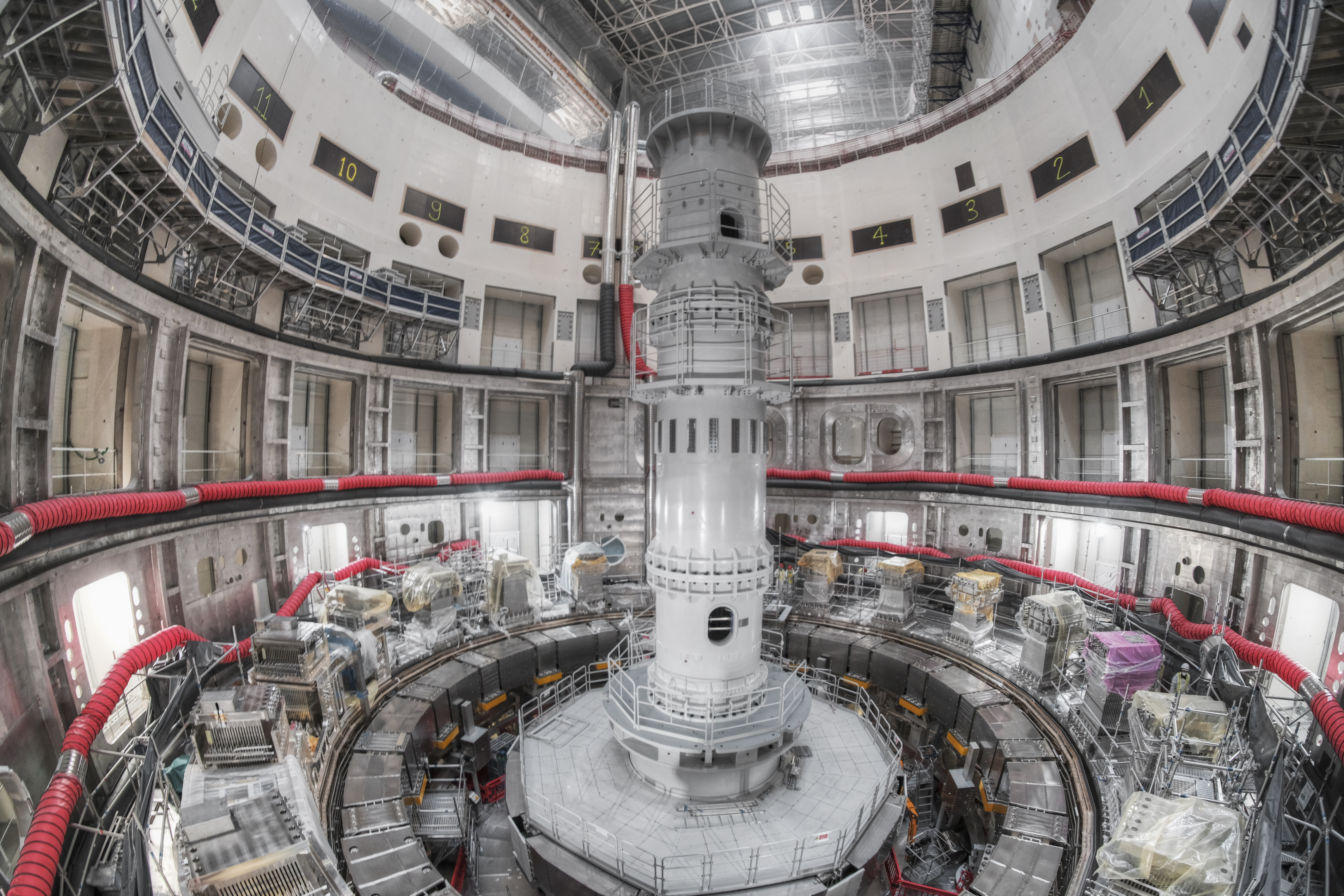

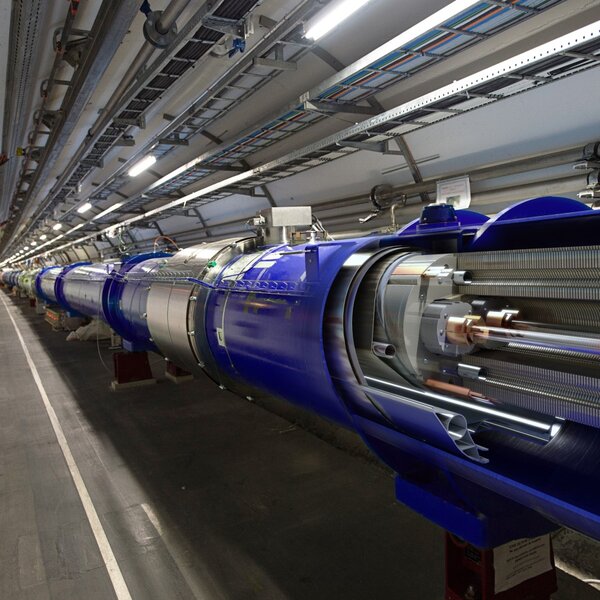

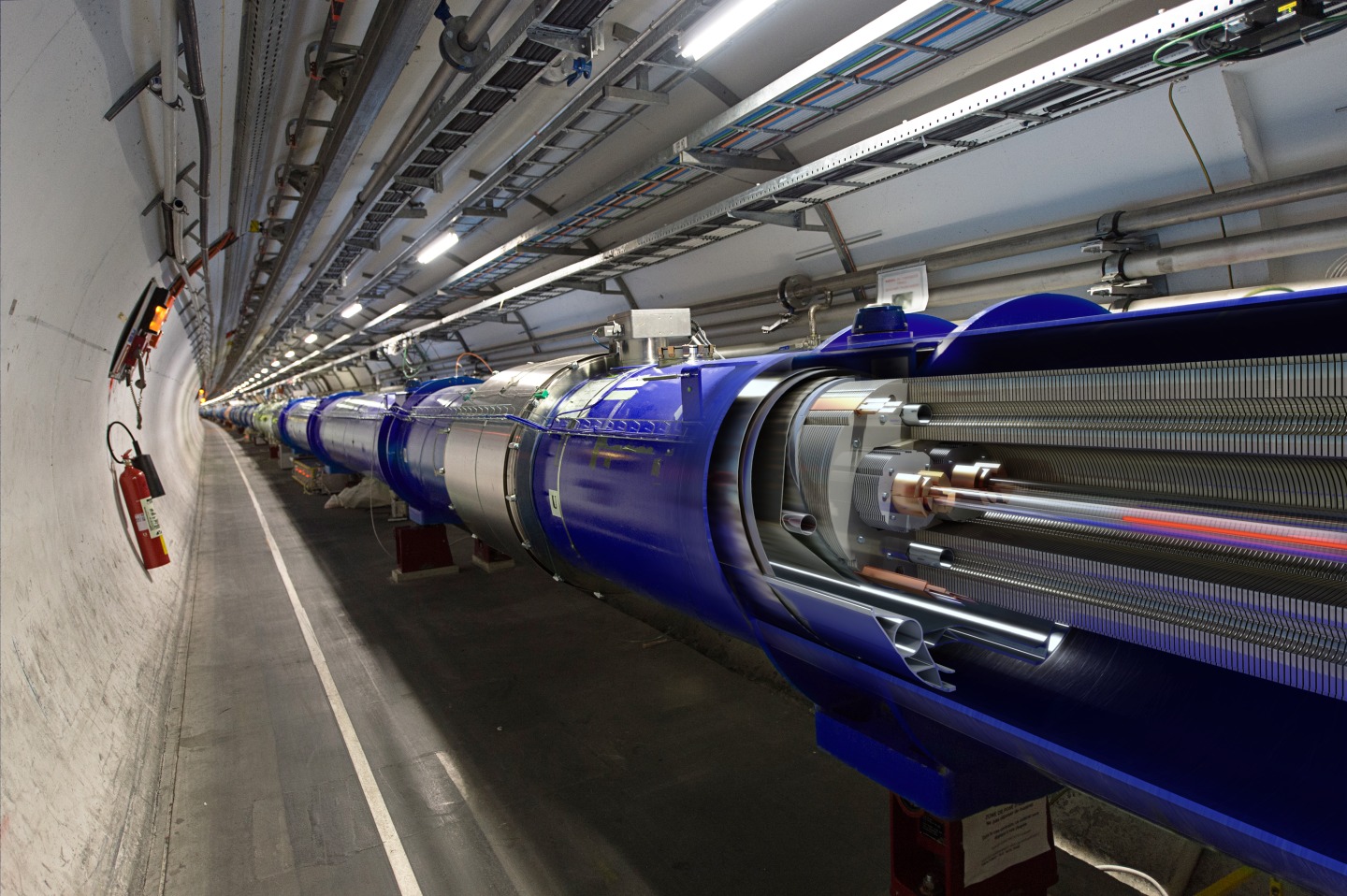

Research facilities, universities and space organizations work under extreme conditions and with the highest demands on technical components. WEKA valves and special solutions are used in critical applications - such as test facilities, large-scale scientific projects or space infrastructure - where technical safety, functionality, durability and adaptability are crucial.

The liquefaction, distribution and storage of technical gases such as hydrogen and helium requires maximum precision and expertise. Our components ensure reliable and stable processes in cryogenic applications - from basic research to the supply of highly complex systems in space travel.

WEKA expertise at a glance

✓ 80+ years of track record in critical research & space infrastructure applications

✓ Specialized solutions for helium and hydrogen

✓ Robust systems for applications in magnetic and radiation environments

✓ Comprehensive expertise in international classification, testing and certification processes

✓ Low-maintenance designs for minimal operating costs

Typical applications

Basic research • Plasma and fusion research • Low-temperature physics • Superconductor cooling • Rocket filling systems

Find the right solution for your application now

Technology for extreme conditions

Unsure about your selection?

Technical Consultation

Our expert team is happy to assist you in selecting the right components – tailored to your specific process requirements regarding material, pressure, and temperature.