WEKA Solutions for Loss-minimized Applications

Helium, hydrogen, oxygen and other gases are liquefied at temperatures well below 0°C and recovered in efficient recirculation systems. Valves are key components of every liquefier and are responsible for regulating parameters and maintaining the optimum operating point. The accuracy and stability of the control system have a significant influence on the efficiency of the plant. At the same time, cryogenic valves connect helium cryogenic lines to room temperature – this unavoidable heat influx must be minimized.

WEKA specializes in high-quality, reliable cryogenic components for fluid temperatures down to 2K (-271°C) – even where the process environment poses exceptional challenges.

Explore our solutions for your demanding helium applications now.

- Plants for liquefaction of helium and hydrogen

- Air separation plants (ASU) for industrial gases

- Gas recovery systems for loss minimization

- Cryogenic cooling systems for superconductors

- Scientific experiments with liquid gases

- Reliquefiers for valuable gases

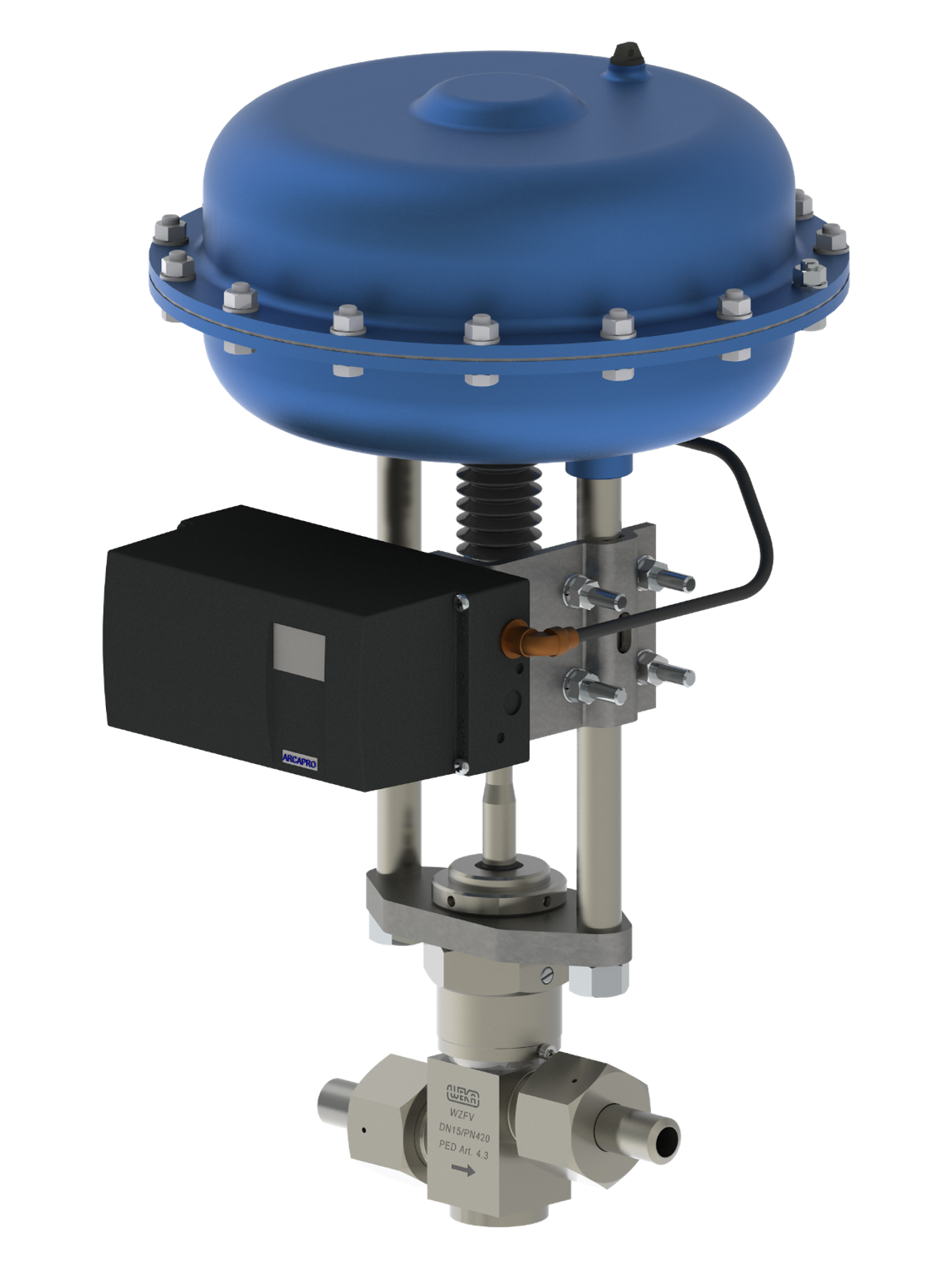

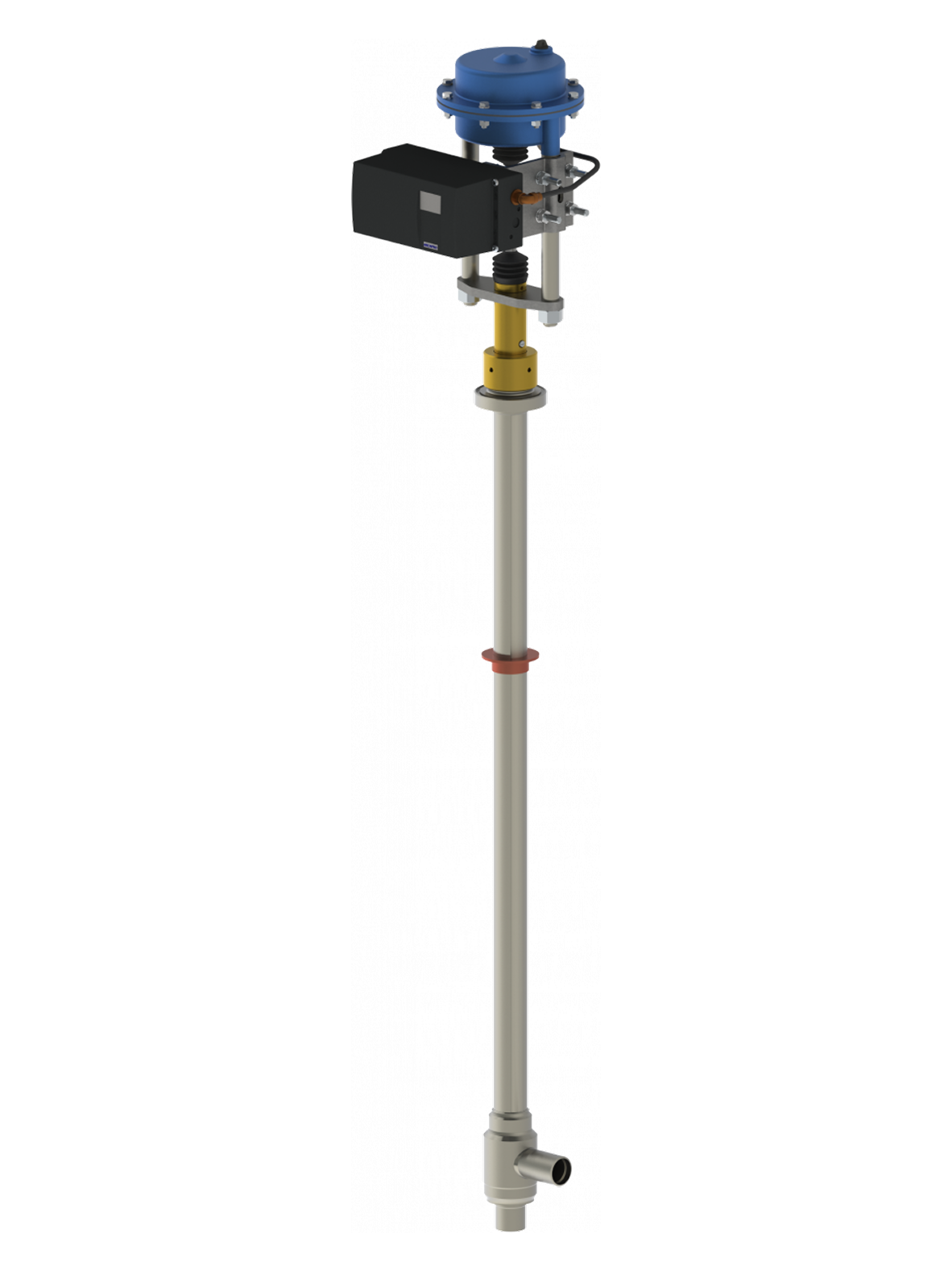

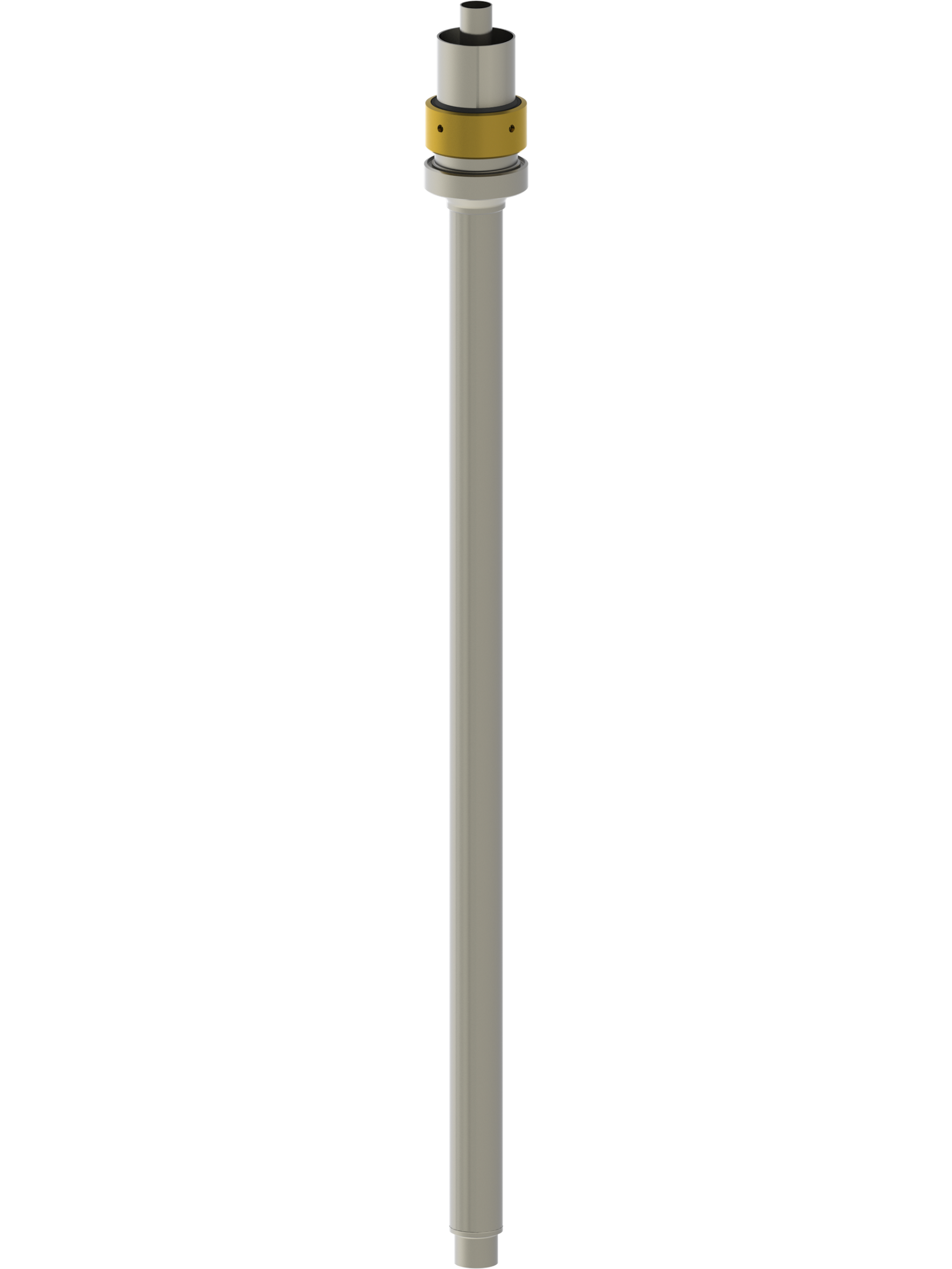

WEKA valves of the TEV and TEQV series have a construction specifically developed for cryogenics, which minimizes heat input and increases plant efficiency.

Transfer line couplings with small gaps and thin metal tubes ensure minimal thermal heat input despite the physical connection, and the BOG recirculation option ensures minimal losses.

Vacuum tightness is crucial for the insulation process of cryogenic plants.

All WEKA components are manufactured and tested with highest quality to guarantee vacuum integrity at every pressure level.

For Gas Liquefaction and Recovery industry

WEKA Products

WEKA Competence

For most applications you will find suitable gas liquefaction and gas recovery solutions from our WEKA standard range.

Special designs for unusual operating conditions with cryogenic valves are possible at any time.

Our strengths include development, production and testing of customized solutions for cryogenic applications.

Get in touch with us – we are happy to advise you on your specific requirements.

Our experts are happy to help

Your personal contact

Expert for: East Asia, Russia, India

Leon Trajber

International Sales Manager Valves & Cryogenics

Send an email+41 43 833 43 22German, English, Slovenian, Serbian, Croatian, Hungarian

Expert for: Europe, Americas, Africa

Miralem Okanovic

International Sales Manager Valves & Cryogenics

Send an email+41 43 833 43 20German, English, Croatian