WEKA Solutions for Corrosive Media

The chemical and pharmaceutical industries use and store highly corrosive liquids that place the highest demands on material resistance. These industries require lower pressures and temperatures, but primarily the reliable handling of highly corrosive liquids.

Explore our proven corrosive media solutions now for your chemical and pharmaceutical measurement technology applications.

- Dosing and intermediate storage tanks for aggressive media

- Desalination plants for water treatment

- Water treatment plants for process water

- Tank farms for chemical logistics

- Chemical process engineering plants

- Cooling systems with corrosive cooling media

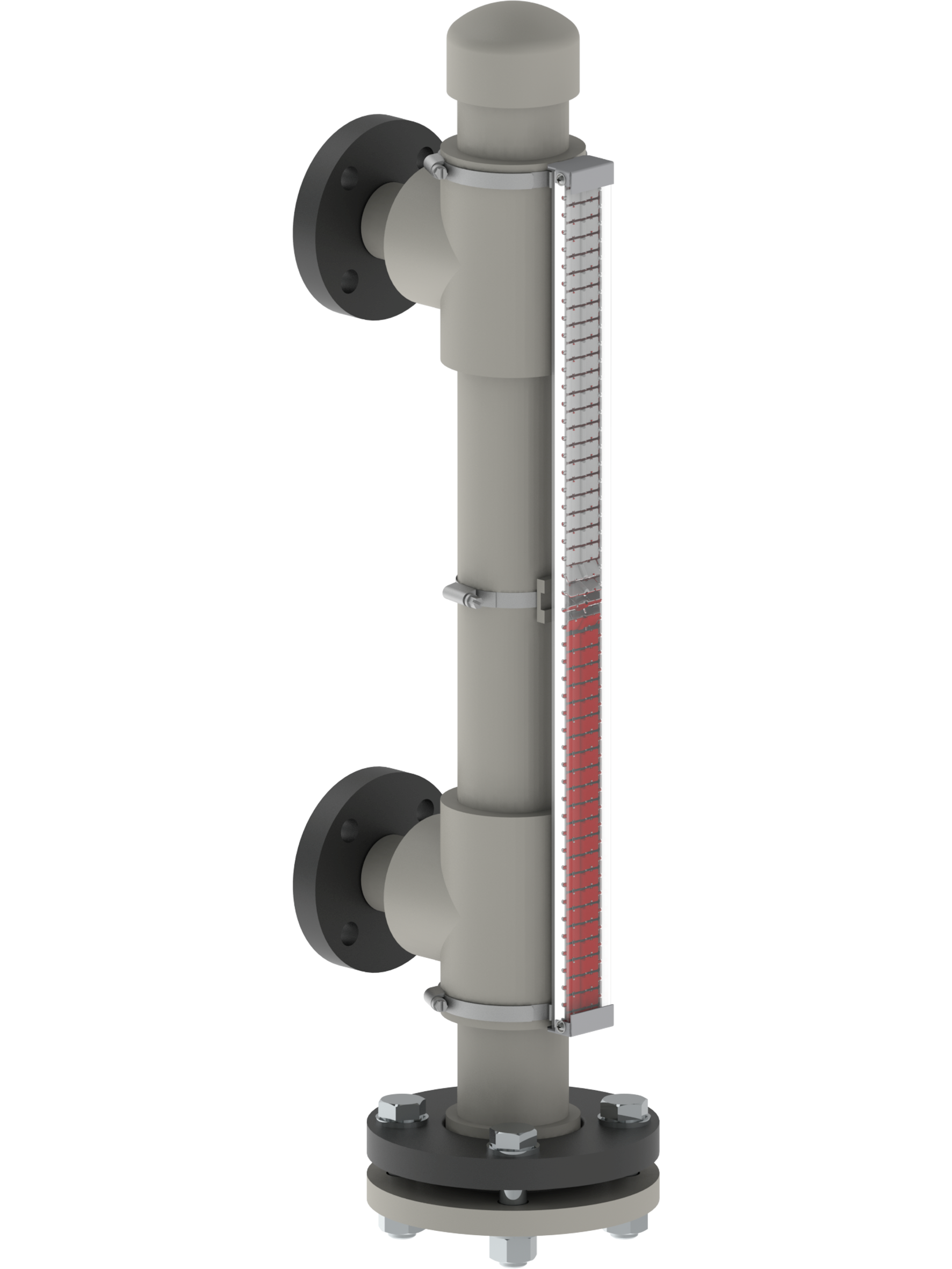

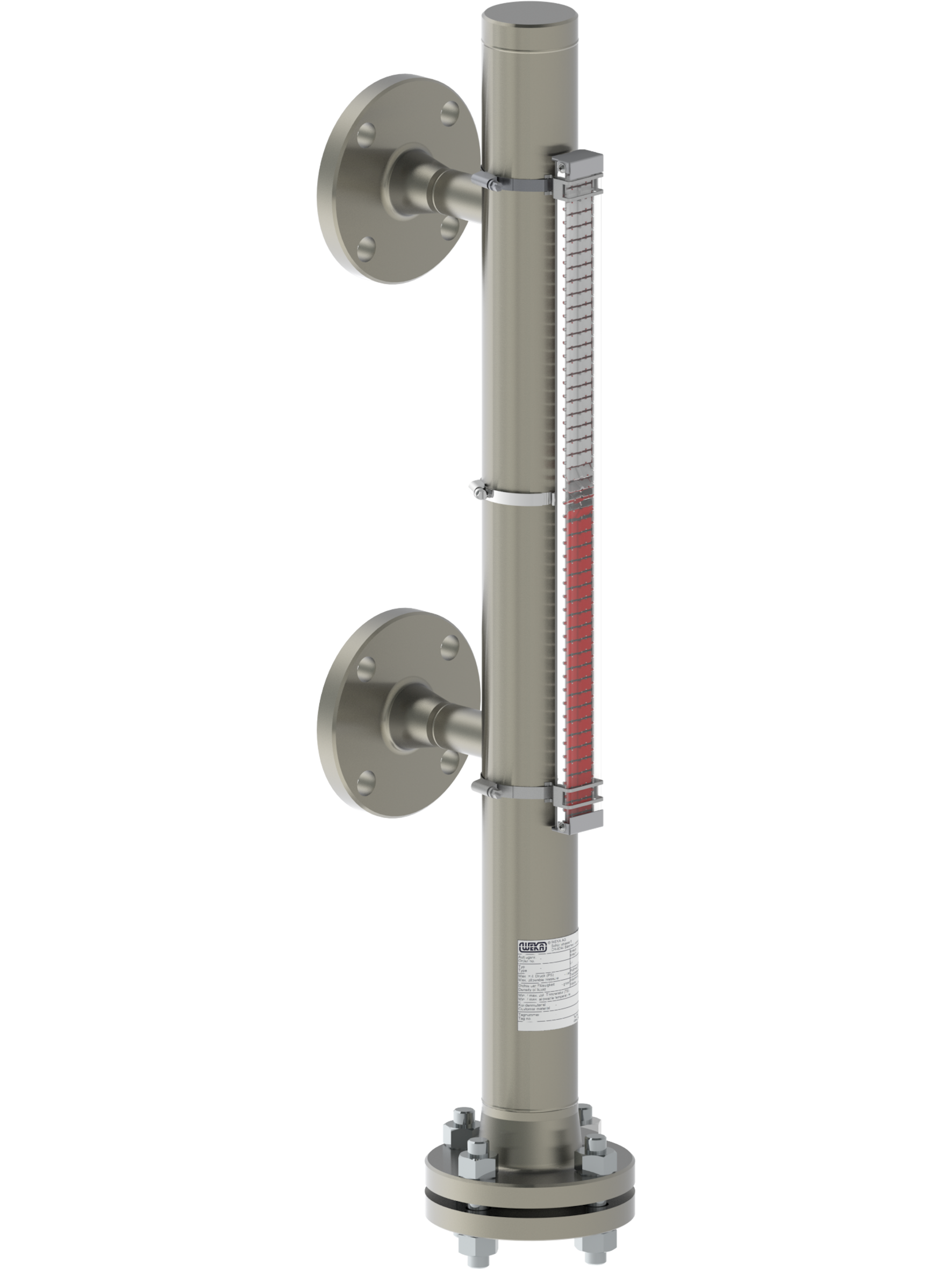

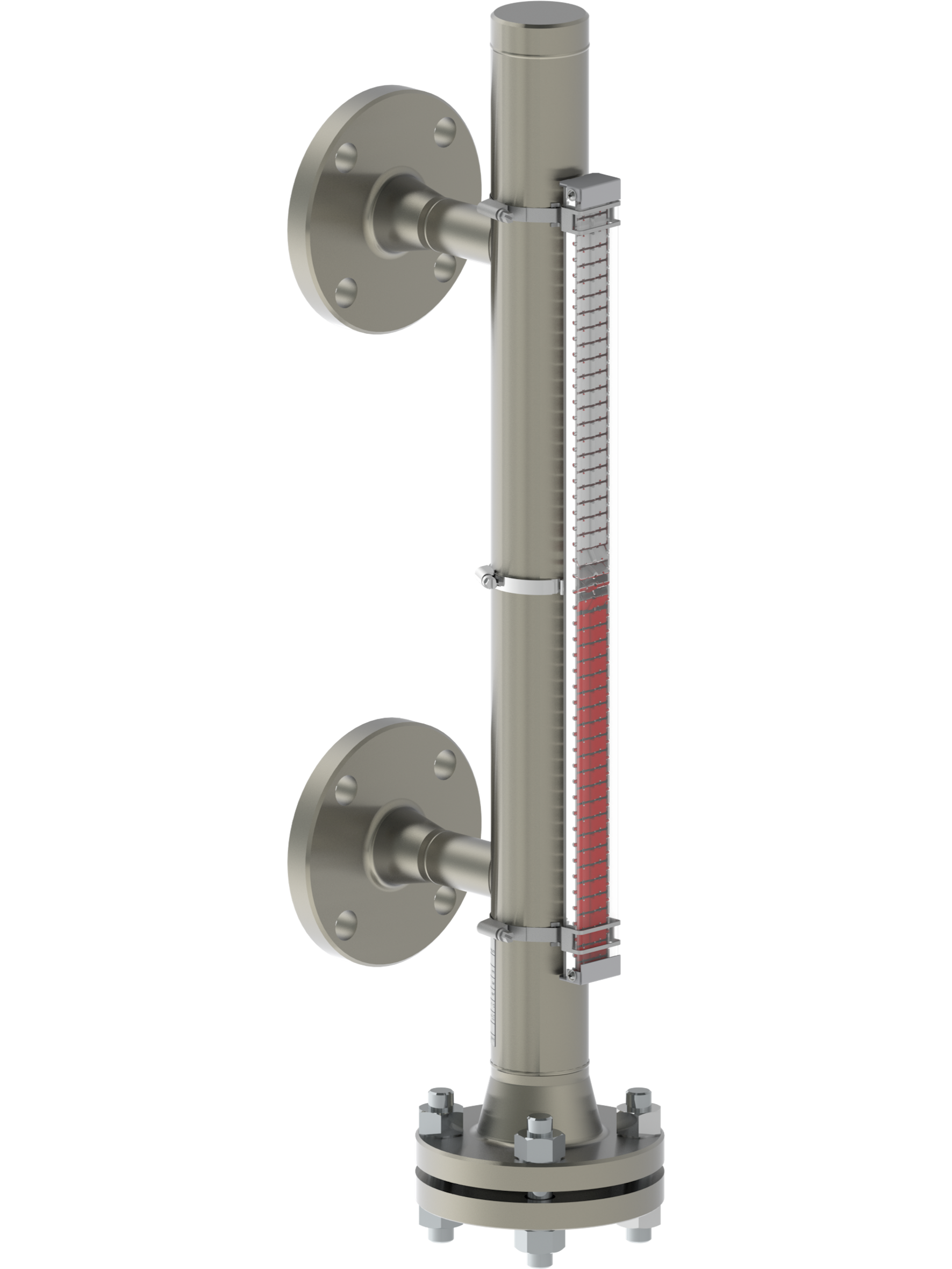

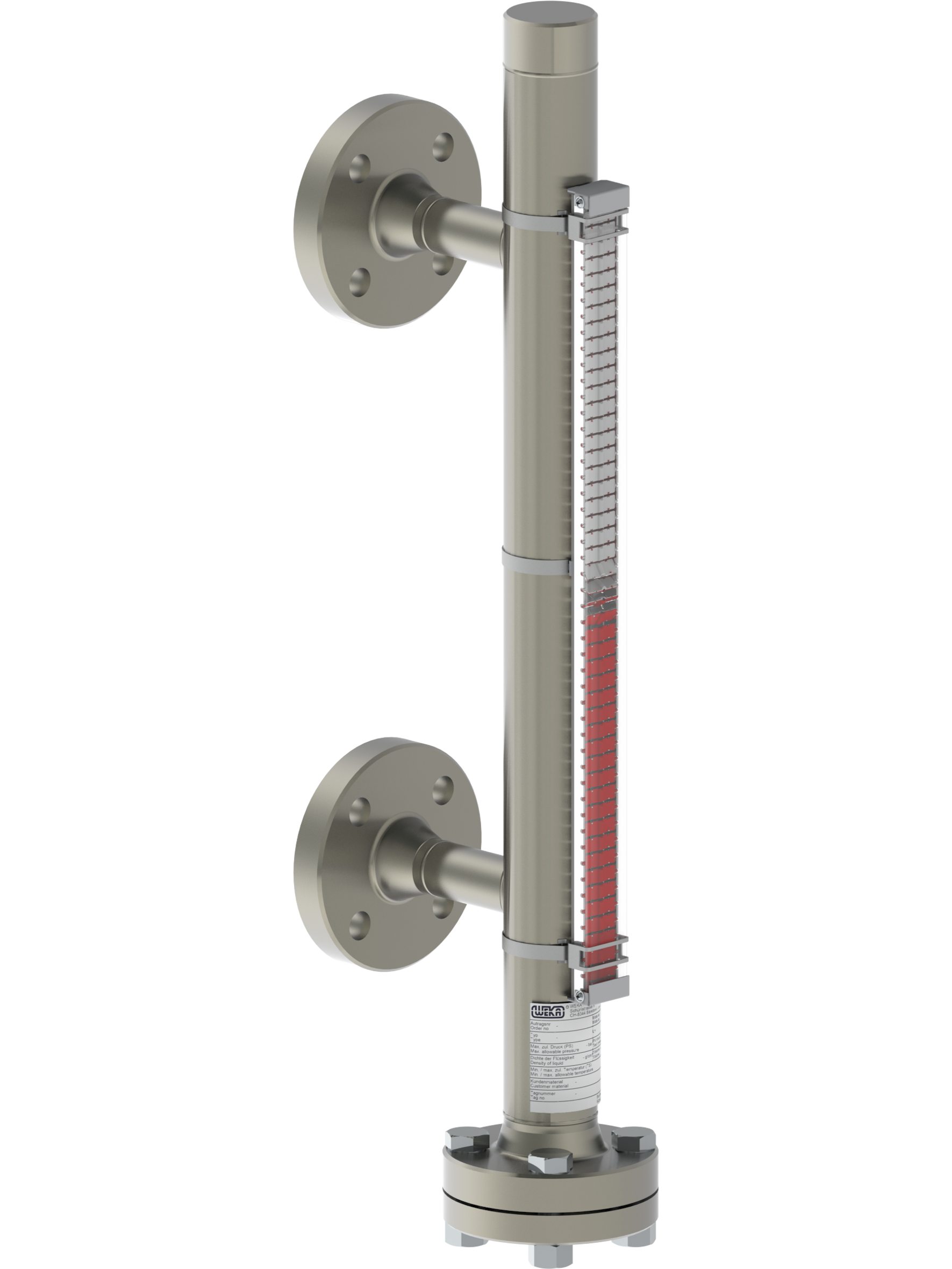

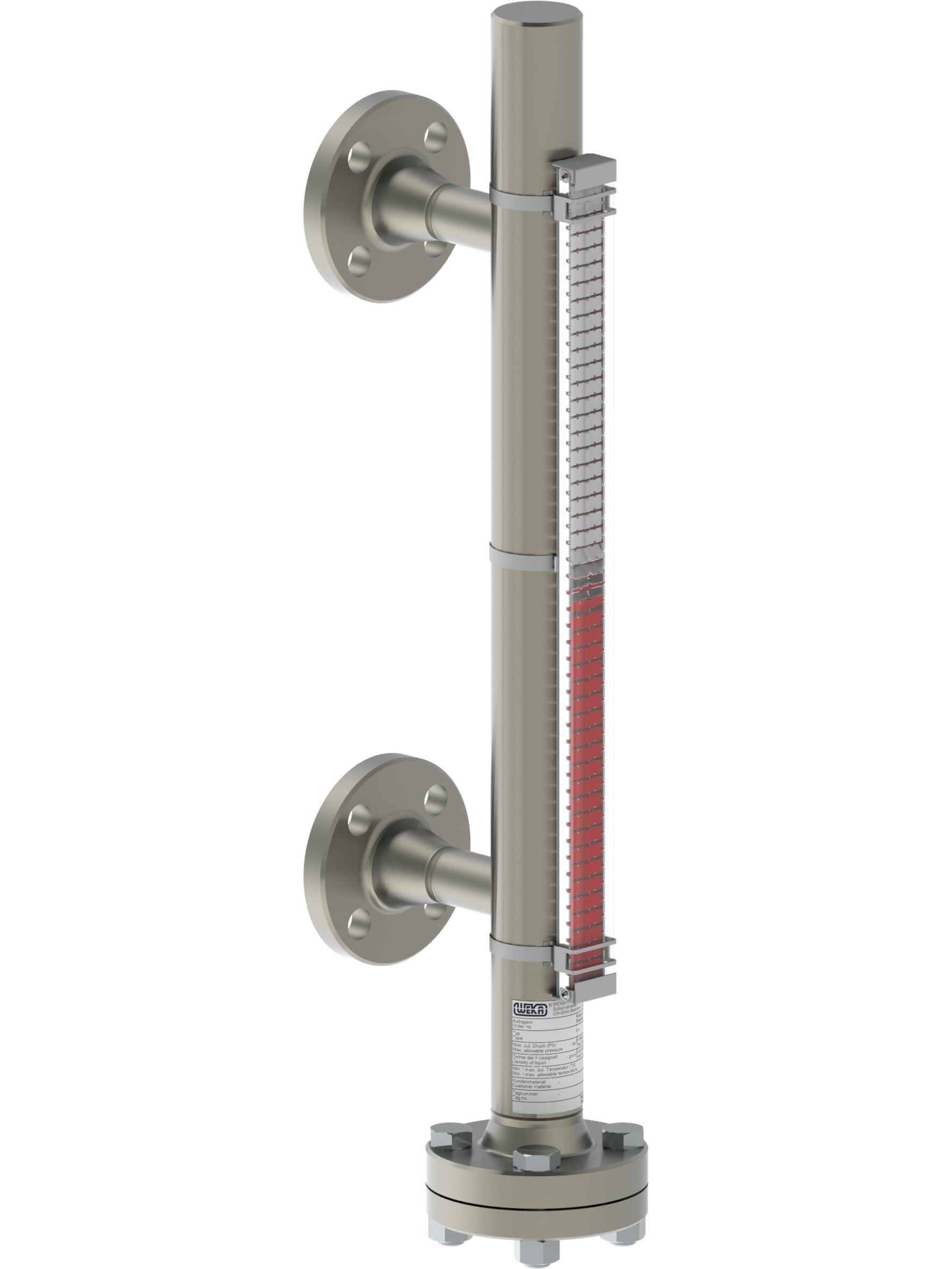

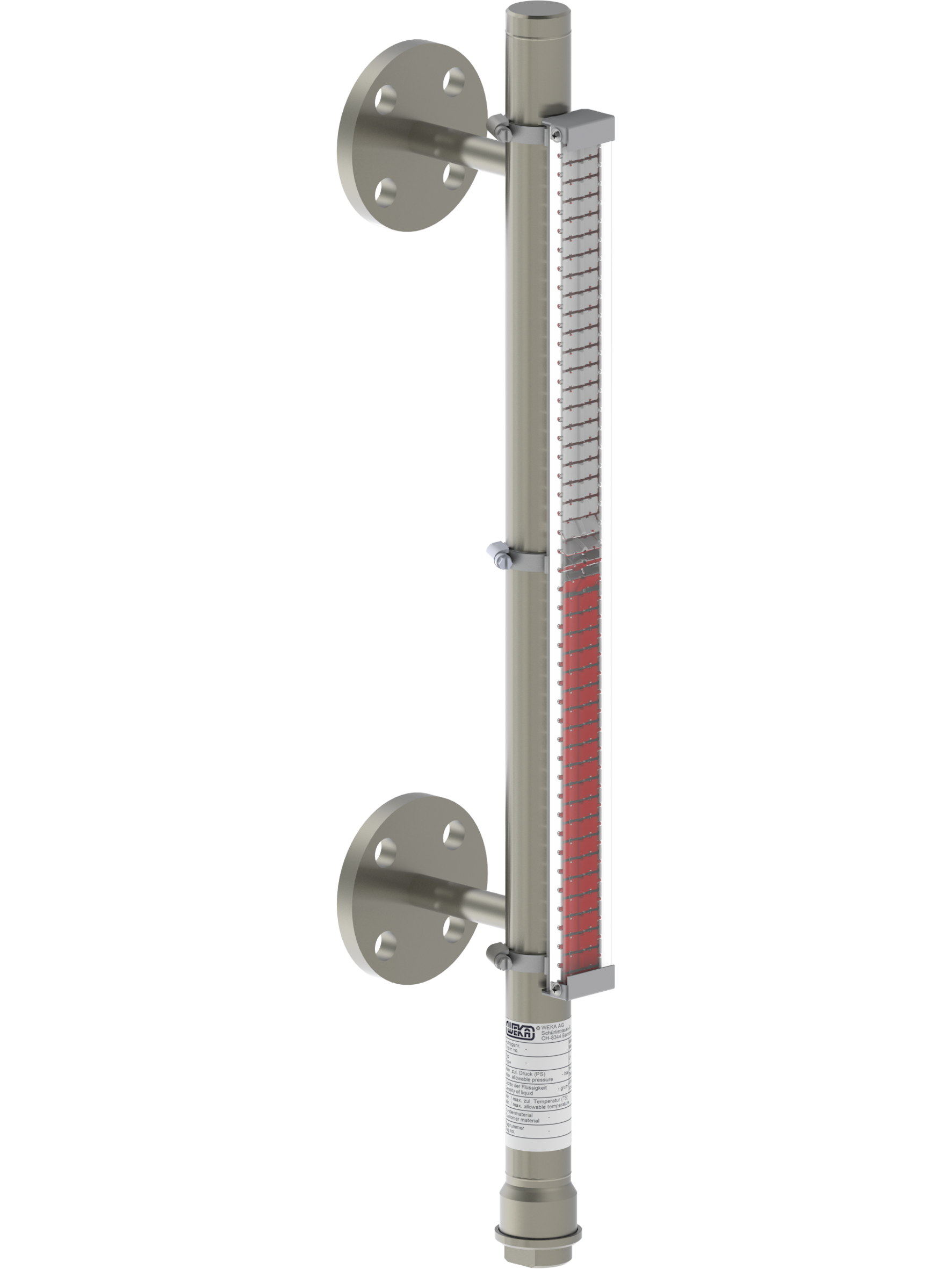

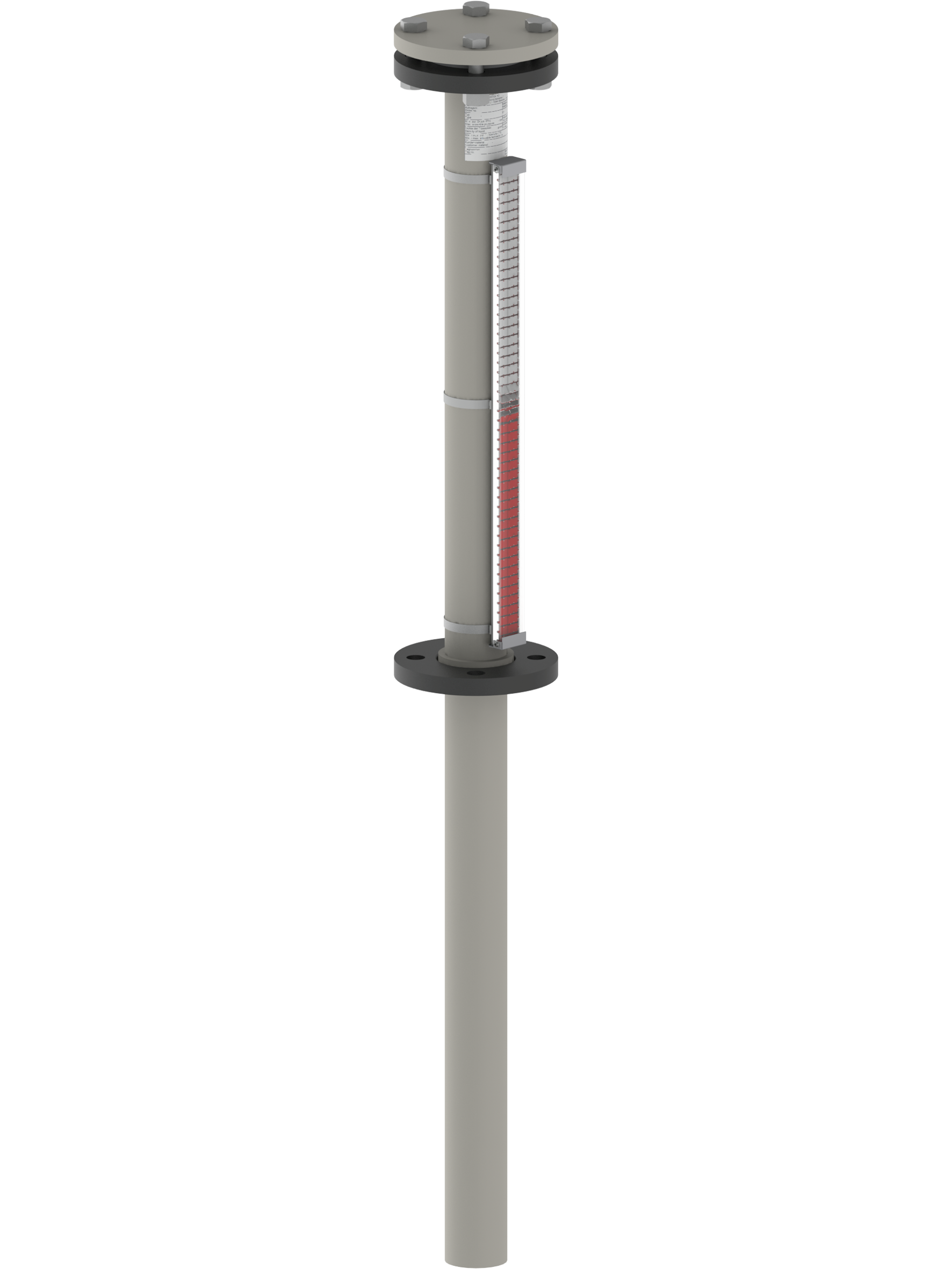

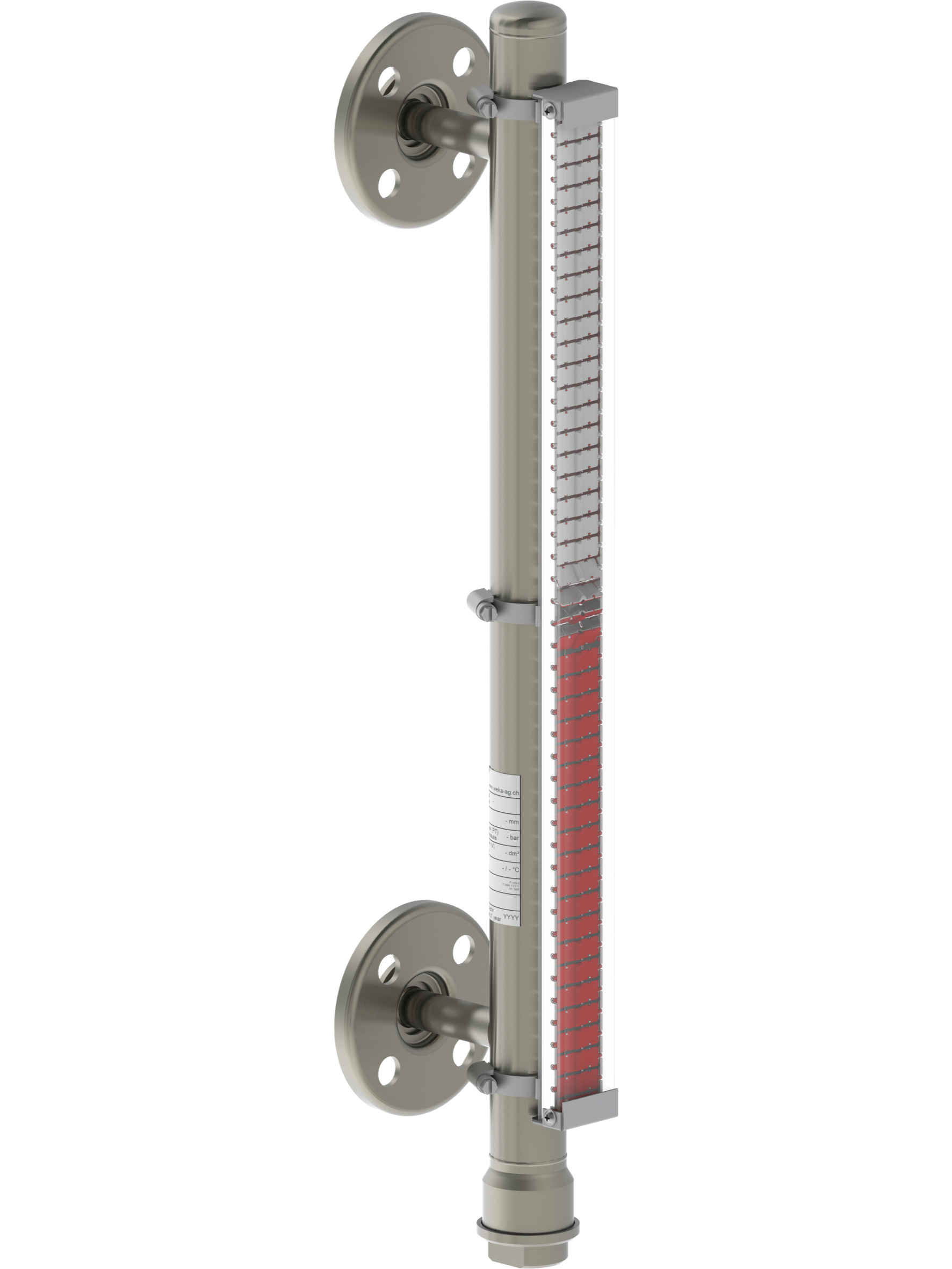

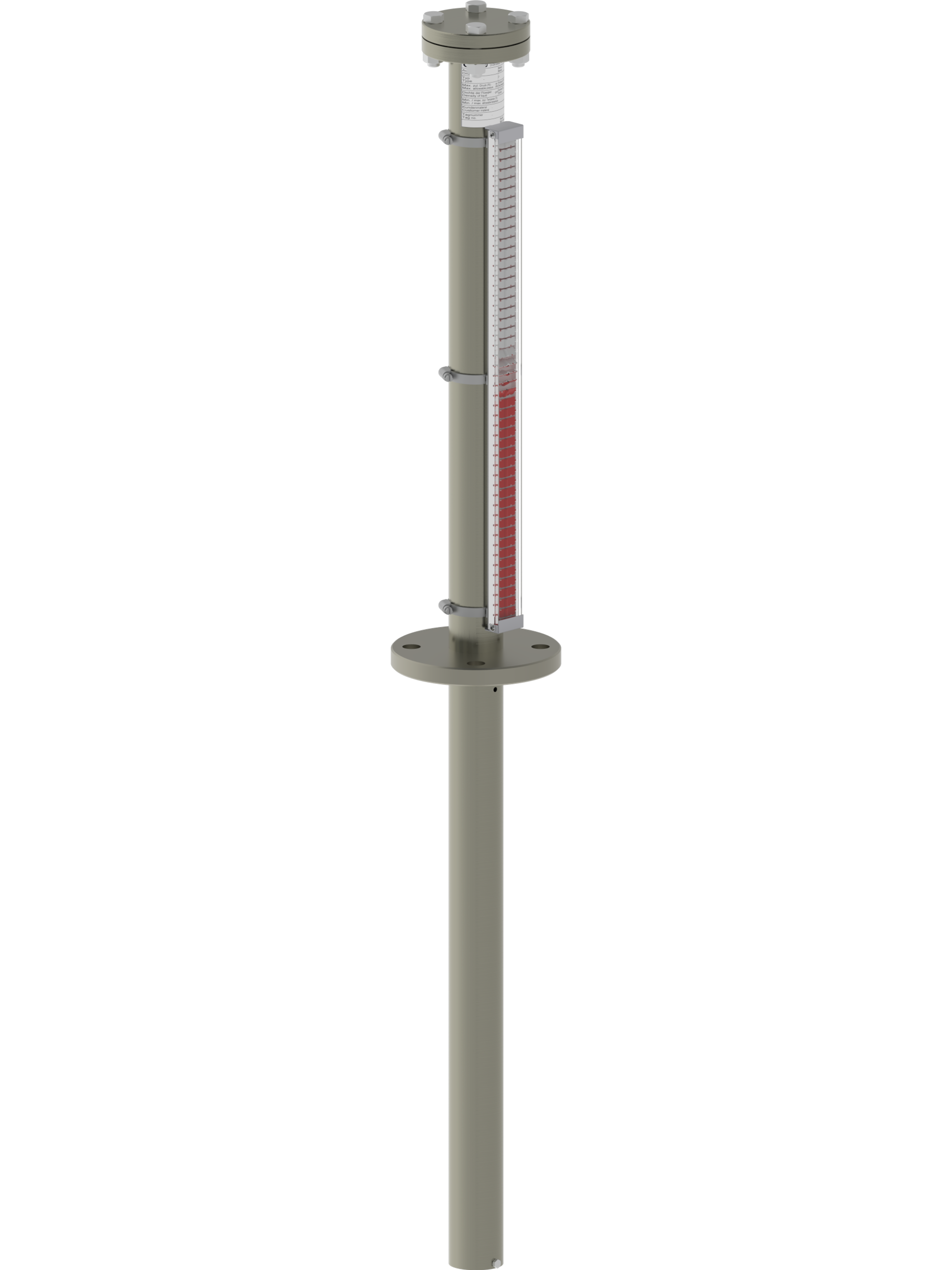

Besides standard designs in 316/316L, we offer specialized solutions made of high-alloy nickel steels for extreme corrosion resistance as well as variants in PVC, PP and PVDF for level measurement.

Our products are designed for maximum quality and safety - developed and certified in accordance with the European Pressure Equipment Directive (PED) with conformity assessment in accordance with module H/H1.

They also meet international standards and - depending on the version - the requirements of ATEX and IECEx certification for use in potentially explosive atmospheres.

The result: maximum operational safety.

For Chemical & Pharmaceutical Industry

WEKA Products

WEKA Competence

For most applications you will find suitable corrosive media solutions from our WEKA standard range.

Special designs for unusual operating conditions in chemical pharmaceutical instrumentation are possible at any time.

Our strengths include development, production and testing of customized solutions for corrosion-resistant applications.

Get in touch with us – we are happy to advise you on your specific requirements.

Our expert is happy to help

Your personal contact

John M. Andrea

International Sales Manager, Senior Engineer Level Instruments

Send an email+41 43 833 43 27German, English, French